Full Service Product Design

Because technical experience is integrated with industrial design, your project will move seamlessly from early concept to production

Research

We will work with you on a clear product specification. This may require researching potential technologies as well as existing products. We can study user needs through interviews with customers.

Innovation

We are experts in lateral thinking to create new ideas and solutions for your project. This often results in patents. We can research prior art, write your draft application and create drawings.

Design

In the concept phase, we create sketches and presentation boards. We consider human factors and ease-of-use. This is when we explore form and styling, branding, and packaging.

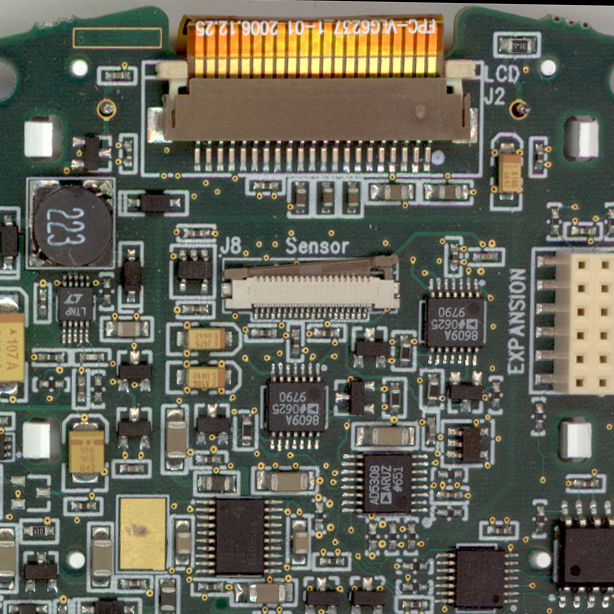

Electrical

We work with electrical engineers to define the circuit, then lay out a board with input and output interface. We also mount LCDs, create battery compartments, and we have experience with EMI/RF.

Mechanical

We create breadboard mock-ups to test designs. We work with mechanisms, motors, and materials. A general design is created in Solidworks CAD that integrates the ID with internal design, with manufacturing assembly in mind.

Prototypes

A realistic working mockup can be created with modern CNC processes in the material of choice, or with rapid 3D printing. Our vendor can create soft tooling for short run testing with customers.

Processes

We have experience with injection molding, die-casting, sheet metal, over molding, cut-and-sew, pressure forming, and optics creation. We strive to design prototypes that are also production-ready.

Manufacturing

Having made our own products, we can create manufacturing documentation including Bill of Materials. We source vendors and provide support during tooling, assembly, test and quality control.